About us

Who are we?

Location

& production sites

Founded in 1965, Trioworld is a Swedish group with headquarters in Smålandsstenar, Sweden.

We are now one of Europe’s leading manufacturers of polyethylene film, with 13 factories in Europe. We produce around 230,000 tons of plastic film (packaging and hygiene film) a year, with our main market being Europe. We also supply our products and solutions to selected customers in countries outside Europe.

Trioworld’s Ombrée d’Anjou production facility is located in Grand-Ouest in the west of France, from where our products are transported to our customers via our logistics centre.

Our production site

24 rue de la Pidaie

49 420 Pouancé - Ombrée d’Anjou

The recycling workshop

Trioworld has had its own recycling workshop since 1985. The main reason for its creation was linked to the management of production waste as well as the processing of used plastic waste, which includes plastic films such as pallet covers, opaque bags, mattress packaging and water bottles, etc. which we transform into pellets, and which are then integrated into our manufacturing formulas. More information about the origin of the recycled material can be found here.

To obtain a quality product based on recycled materials, we first have to carefully select the polyethylene waste and sort it according to its type.

The used plastics are checked when they are received, after which they are converted into pellets. We then check the grade and colour of the pellets.

In 2012, we opened two recycling lines. They allow the recycling of 12,000 tons of plastic per year.

Trioworld was one of the initiators of the recycling of used agricultural films (Commission Agriculture Plastiques et Environnement).

The recycling workshop was developed in 2021. It is a transformation project over 48 months that is taking place in our recycling workshop, an investment alongside ADEME.

The two existing manual sorting lines have been fitted with an automated sorting system.

The new recycling equipment will allow us to be much more flexible in terms of the grades of PCR (post-consumer recycled) entering our site.

It will also allow us to double our PCR waste processing capacity to almost 20,000t/year, while maintaining the high quality of regranulates that we are known for.

At Trioworld, we think about the environment in everything we do.

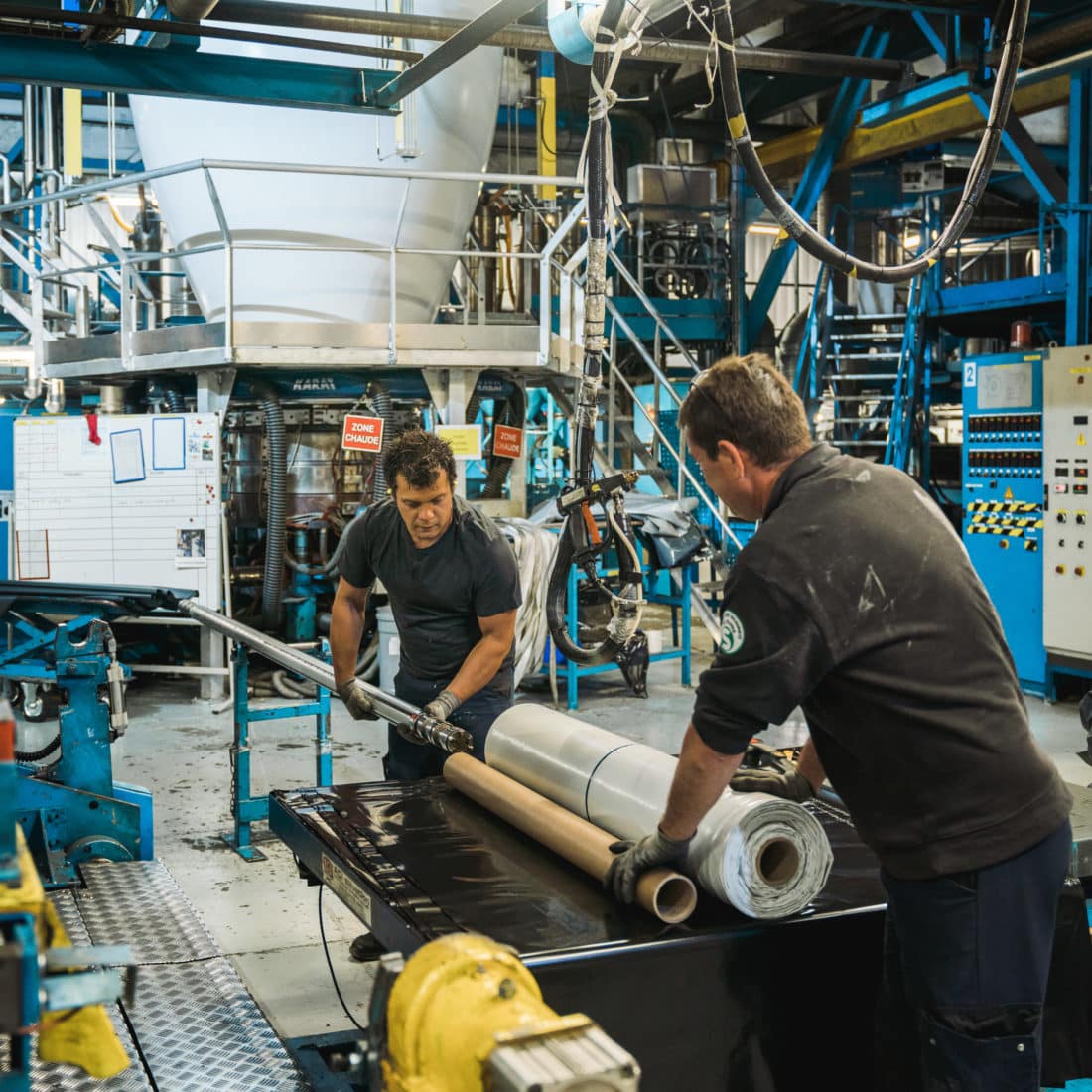

The extrusion workshop

Extrusion blow moulding is the process of transforming Polyethylene pellets derived from oil or gas and mainly from recycled plastics. As the blown tube (bubble) is inflated and drawn, the film is reduced in thickness to form the desired finished product.

Trioworld has over 50 years of expertise in extrusion blow moulding. All production is carried out in our own workshop located at our production site in France at Ombrée d’Anjou in the Maine-et-Loire department. Our different production lines allow us to produce silage film, film wrap and horticultural film.

Our different production lines allow us to produce films for agriculture ranging from 1m50 to 18m in blown tube (bubble) diameter, reel lengths from 20m to 2000m, and thicknesses ranging from 21 to 180 microns, all available in a wide range of colours.

Our know-how and expertise mean we can meet the standards of both industrial and product certifications (link to certifications).

Sensitive to environmental issues, Trioworld is committed to integrating ever more recycled material in its production, reaching up to 96% today. Our expertise allows us to manufacture 100% recyclable mono-material films.

The selection of raw materials, the creation of our formulas and our manufacturing processes allow us to produce high quality silage films that will give you the best possible forage protection.

We are constantly working closely together with our customers and partners to develop our range to fit your needs in the best way.

Direct customer access

Direct customer access